Sugeng rawuh ing situs web kita!

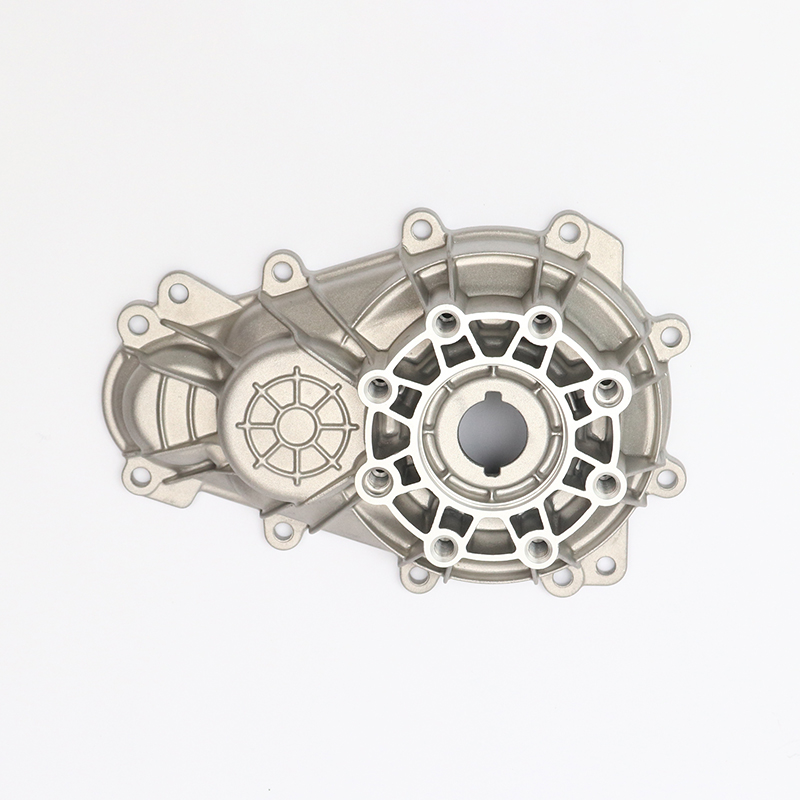

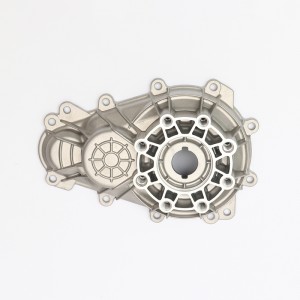

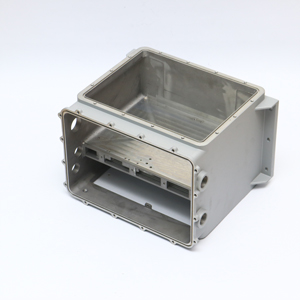

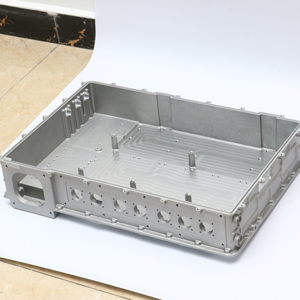

Custom Aluminium Alloy Die Casting bagean kanggo Automobile Transmission Housing Case Gearbox Cover

Fenda Aluminium Die Casting Parts

| Bahan cetakan | PH13, H13, DVA utawa minangka saben request |

| Mold urip | 50000shots , utawa minangka saben request |

| Bahan Produk | Aluminium alloy ADC10, ADC12, A360, A380 lan minangka saben request |

| Perawatan lumahing | Polishing, Shotblasting, Sandblasting, Painting, Powder coating |

| Proses | Gambar & Sampel → Pembuatan cetakan → Die casting → Deburring → Pengeboran lan Utas → Mesin CNC → Polishing → Perawatan permukaan → Majelis → Inspeksi kualitas → Packing → Pengiriman |

| Mesin die casting | 280T/400T/500T/630T/800T/1250T/1600T/2000T |

| Format nggambar | step, dwg, igs, pdf |

| Sertifikat | ISO/TS16949:2016 |

| Sistem QC | 100% inspeksi sadurunge packaging |

| Kapasitas Saben wulan | 40000PCS |

| Wektu timbal | 25 ~ 45 dina kerja miturut jumlah |

| Syarat-syarat pembayaran | T/T |

| Aplikasi | 1, bagean Otomotif 2, omah lampu LED lan heat sink 3, Alat daya 4, piranti gas 5, mesin tekstil 6, Telekomunikasi 7, Aksesoris Furnitur 8, bagean Mekanik liyane |

Profil Pabrik

Fokus ing desain lan manufaktur cetakan aluminium die casting, aluminium alloy die casting lan mesin CNC.

Didegaké ing 2006.

15000 meter persegi area tanah tanduran.

Luwih saka 30 teknisi lan insinyur.

4 set mesin EDM, 4 set mesin WEDM.

6 set mesin die casting kamar kadhemen saka 400T nganti 2000T.

80 set pusat mesin kanthi kacepetan dhuwur / tliti.

30 set welding gesekan aduk kanthi tliti dhuwur, perawatan permukaan lan mesin khusus presisi liyane

1 set Zeiss CMM , 1 set Eduard CMM, 1 set industri CT, 1 set spektrometer Oxford-Hitachi lan sawetara set tester sesak gas.

Tulis pesen sampeyan ing kene lan kirimake menyang kita